WE STRIVE TO MINIMIZE OUR ENVIRONMENTAL FOOTPRINT AT EVERY LEVEL.

GREENSHOUSE GAS

Tackling climate change requires ambitious action, and we believe the time is now. Our approach is to avoid, reduce, and compensate.

AVOID

We use 100% renewable energy in our office and store.

REDUCE

80% of our products are manufactured in Europe, which reduces transportation distances and greenhouse gas (GHG) emissions. When planning sourcing and production, we consider the location of our fabric suppliers and manufacturers to avoid long transportation routes. For example, the supply chain (from farm to manufacturer) of our fully traceable leather items is entirely located in Turkey. We consciously select fabrics, incorporating more recycled and lower-impact materials that require less energy during production. Learn more about the materials we use here.

COMPENSATE

While not all of our CO2 emissions can be avoided or reduced (yet), we take responsibility by offsetting the carbon footprint of parcel deliveries, returns, and our online shop operations. We work with Klimakollekte and offset emissions through Gold Standard certified projects. Additionally, all sea-freight shipments from China are compensated via our logistics partner Forto.

We are continuously working to avoid and reduce GHG emissions in our business operations and supply chains. Since the majority of emissions in the fashion industry occur in supply chains, our next step is to dive deeper into our Impact Assessment data to identify further reduction opportunities and develop effective actions.

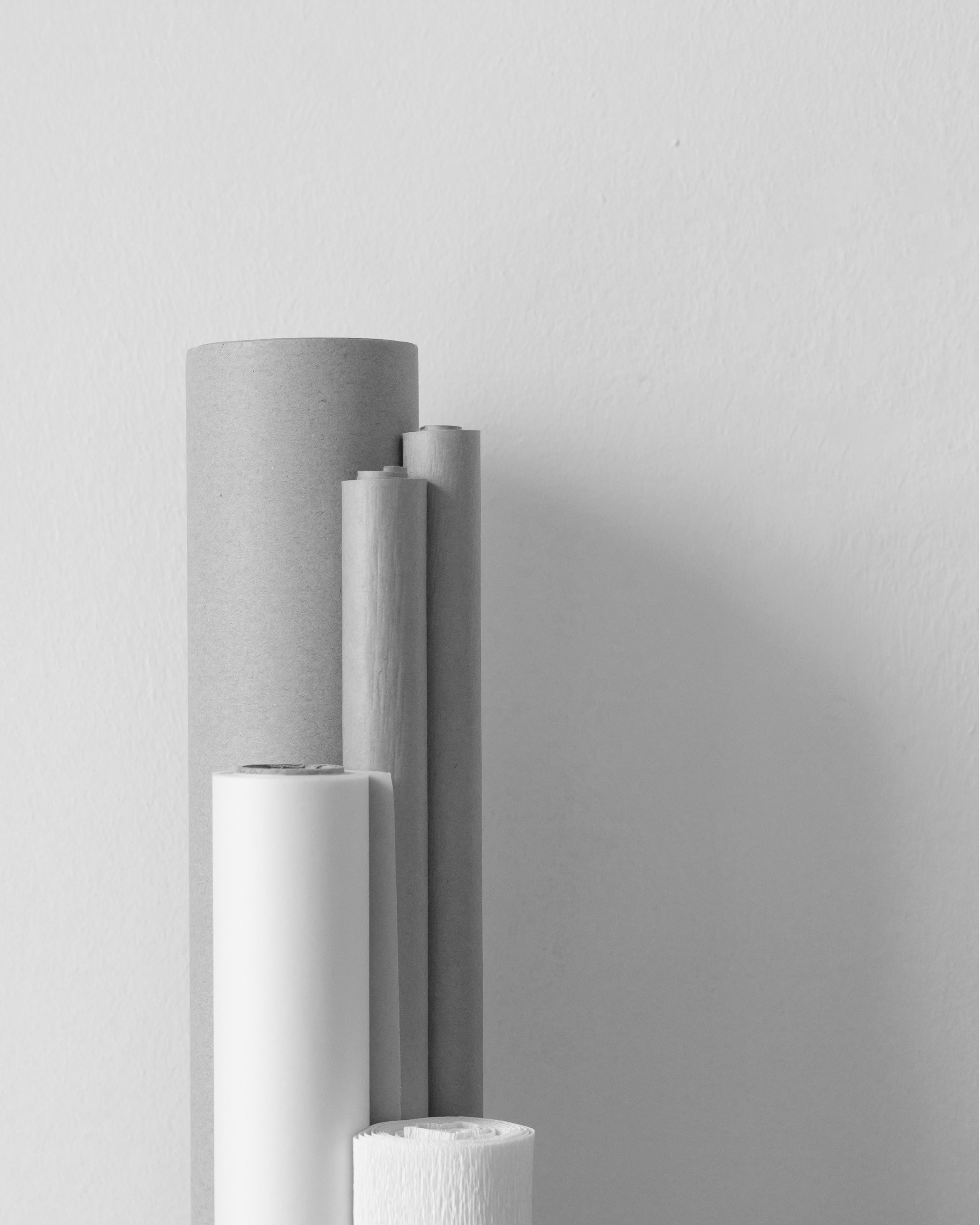

Packaging

For packaging, we follow the principles of reduce, reuse, and recycle. Since 2020, we have partnered with Canopy through the Pack4Good initiative to reduce our packaging footprint and source materials from responsibly managed forests. Learn more about this here.

All of our boxes, hang tags, and polybags are made from recycled and recyclable materials. Our invoice envelopes and paper are Blue Angel certified recycled paper. For small and medium orders, we use shipping bags instead of cardboard boxes. These bags, produced in Berlin, are lighter and take up less space during transport, reducing GHG emissions. Additionally, the bags can be easily reused by customers.

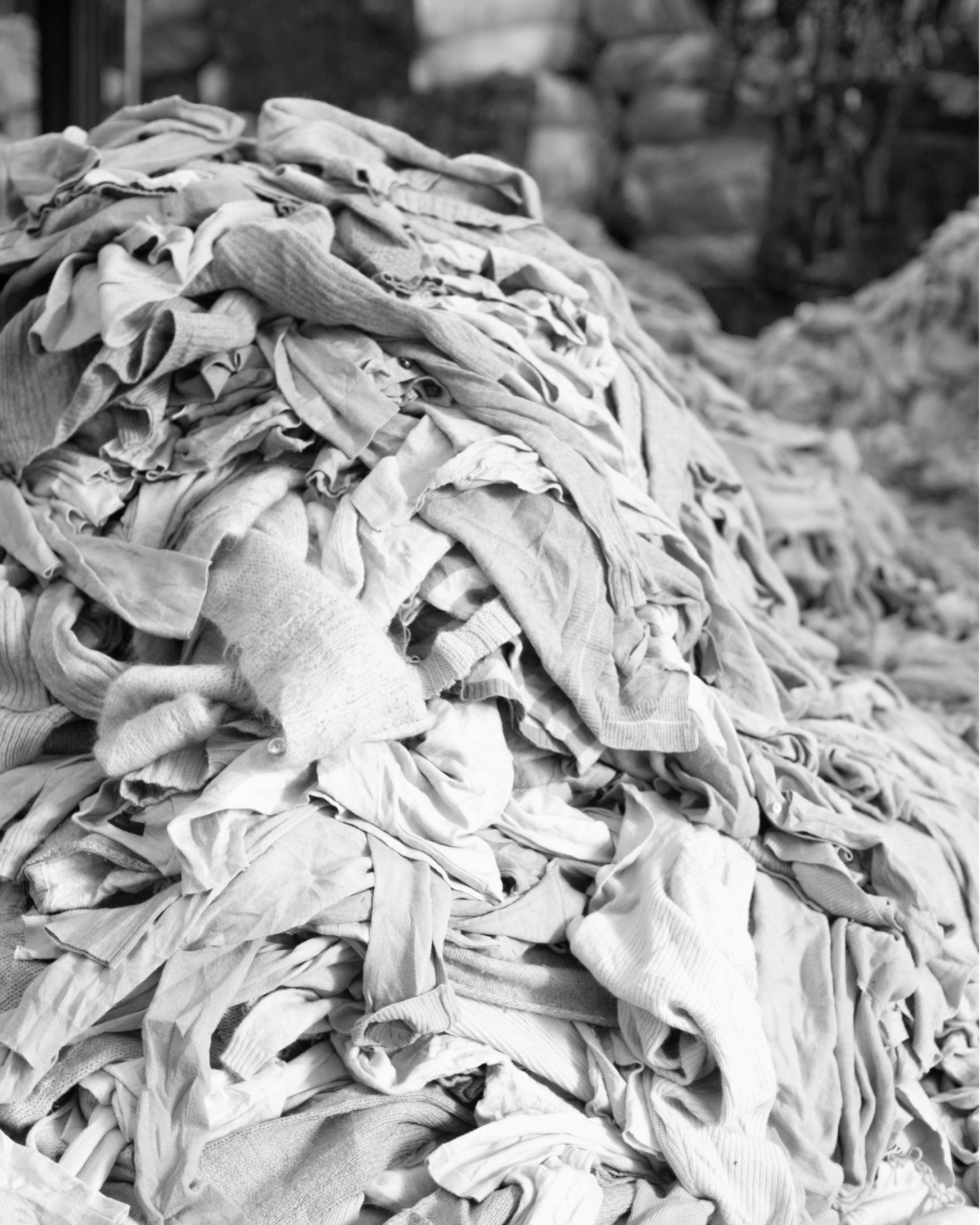

Waste

We are conscious that garment and fabric production requires valuable resources, and we are committed to minimizing waste. Through various partnerships, we ensure that our design process generates as little waste as possible. We follow a no-landfill policy for all deadstock and defective items.

Prototypes and samples are repurposed in our sample sales or given to our team. Fabric samples and early prototypes are donated to local upcycling workshops, sewing cafés, or universities. Leftover fabrics are either reused in future collections or made available to other brands. Unsold items from previous collections are given a second life through our partner Otrium. We also ensure that returned items do not become waste. If a returned item has a minor defect, such as a loose button, it is repaired by a partner company.