INTRODUCTION

At IVY OAK, our work is guided by a commitment to product quality, longevity, and transparent production standards.

In this report, we share the key facts behind our Fall/Winter 2025 collection — including material choices, production locations, and ongoing efforts to strengthen transparency and reduce our environmental impact. This year also marks an important moment for our brand. With the establishment of a new company structure in partnership with DK Company, IVY OAK is entering a new phase. Access to DK’s infrastructure and ESG expertise enables us to build on our existing work and further develop our processes.

This report provides an overview of what we have achieved so far and where we aim to improve as we continue evolving in this new chapter.

MATERIALS & INNOVATION

BUILDING DURABLE AND TRANSPARENT COLLECTIONS

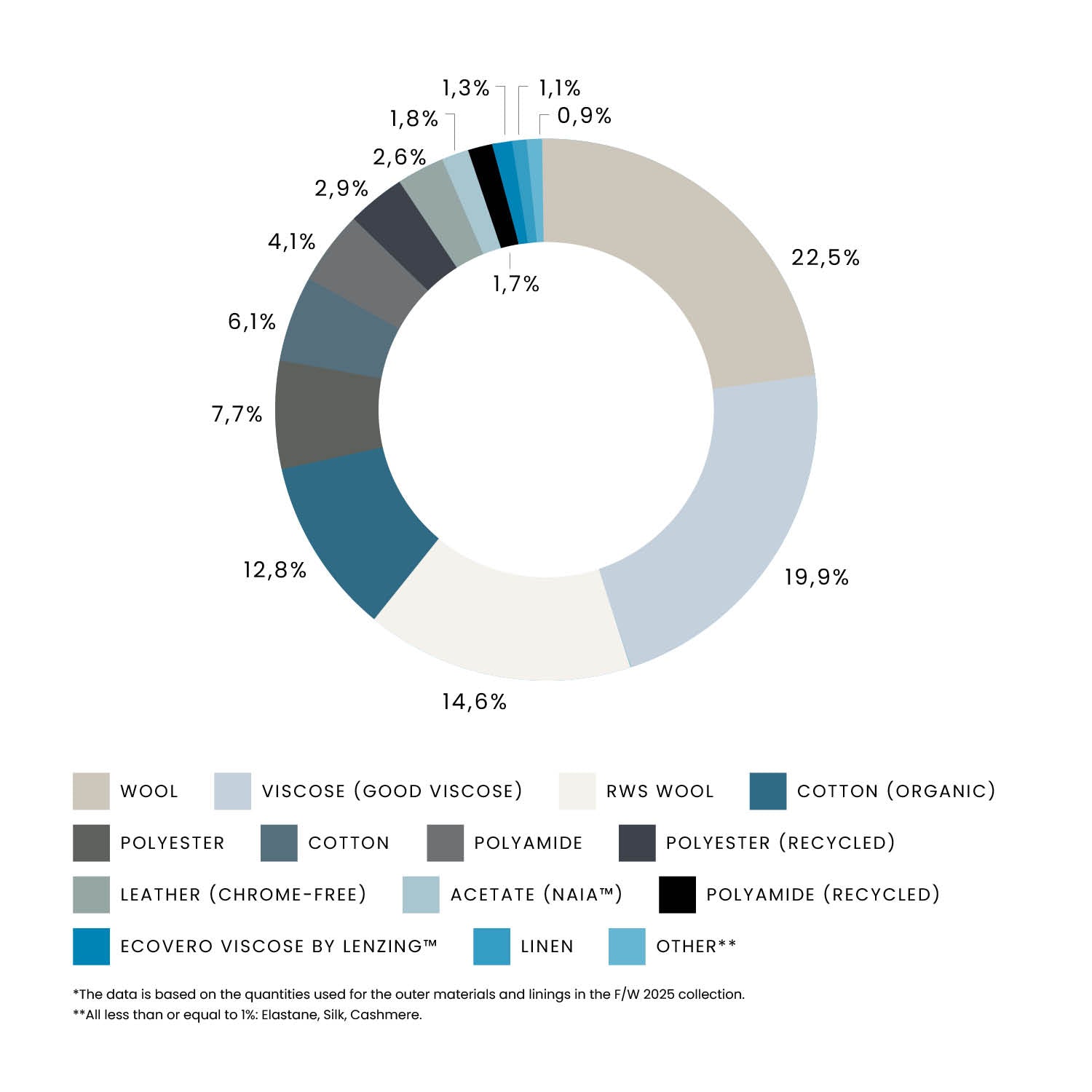

In the Fall/Winter 2025 collection, we focused on creating a stable and balanced material mix, consolidating our portfolio and strengthening product quality. Natural and man-made cellulose fibres form the core of the collection, complemented by selected synthetics for performance and durability.

Wool remains a key component, accounting for 22.5 % of the collection, with RWS-certified wool at 14.6 %. RWS wool ensures traceability and adherence to defined animal welfare standards, giving confidence in the quality of the fibre we use for tailored pieces.

Cellulose-based fibres – including regular viscose and lower-impact options such as Ecovero™ and NAIA™ acetate – make up over 23 % of the collection, while organic cotton remains a stable component of the mix. Together, RWS wool, organic cotton, Ecovero™, and NAIA™ acetate make up a significant share of the collection, reflecting a focus on fibre traceability and quality. Conventional cotton is applied where it best supports structure and longevity.

This season marks a shift from active material experimentation to stability – embedding quality, transparency, and durability across the collection.

BALANCED FIBRES, SMART SELECTION

FOCUS ON NATURAL AND PLANT-BASED COMPONENTS

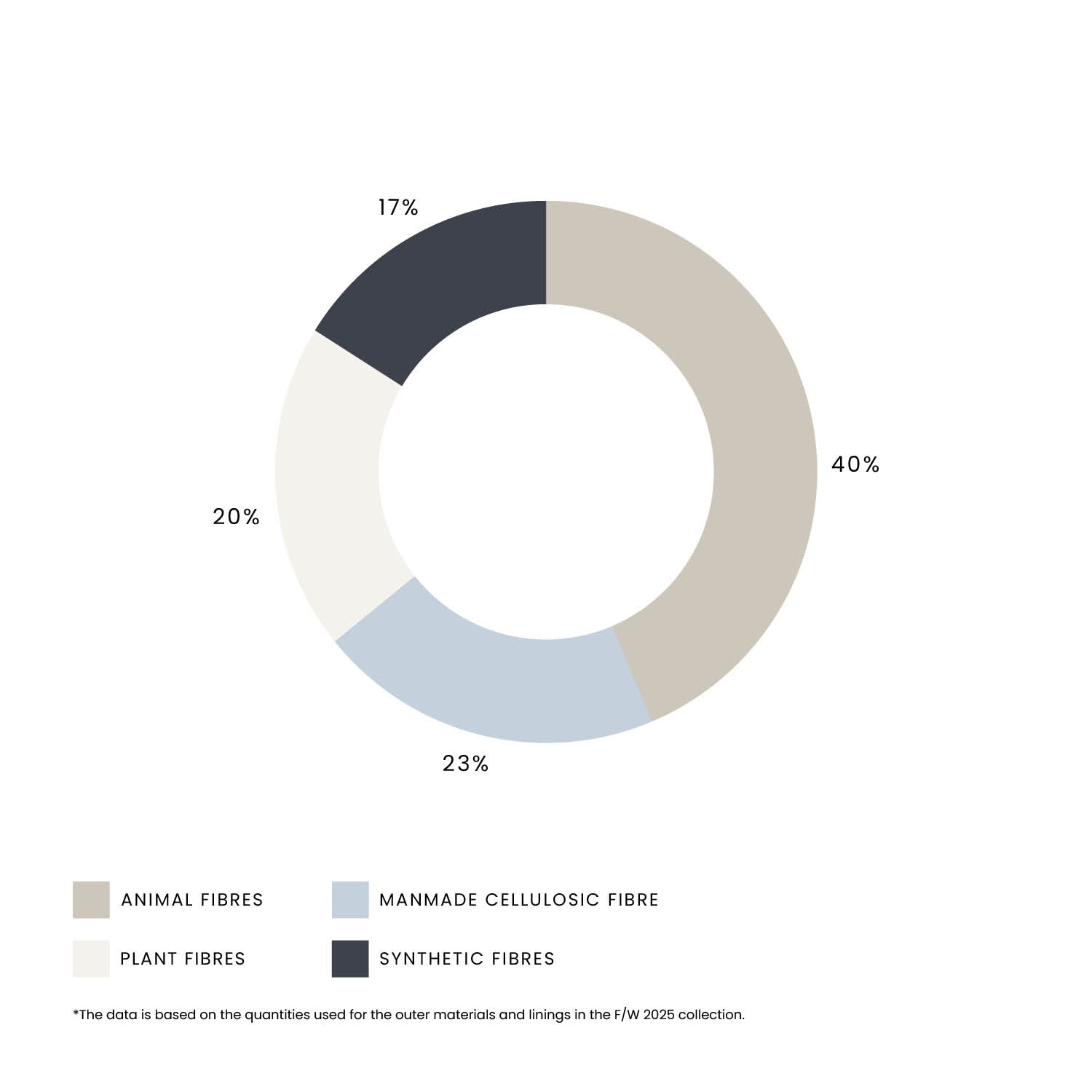

In our Fall/Winter 2025 collection, animal fibres make up the largest share of our material mix at 40%, reflecting a return to more substantial fibres after previous seasonal fluctuations. Man-made cellulose fibres account for 23%, providing balance between natural and functional materials. Plant fibres have steadily increased since F/W 2023 and now represent 20% of the mix. Synthetics remain stable at around 17%, applied where needed to support durability and fit.

In line with the categories defined in our Preferred Material Framework, we are committed to gradually increasing the share of Category A and B materials each season, while recognising that the specific product mix in each collection influences the overall ratios.

Here is the breakdown for F/W 2025:

- Category A materials: 38% (Target)

- Category B fibres: 24% (Target)

- Category C materials: 4% (Transition)

- Category D fibres: 34% (Transition)

Overall, F/W 2025 shows a balanced fibre mix, with natural fibres stabilising and plant-based alternatives gradually increasing, while certified and traceable fibres continue to support quality and transparency.

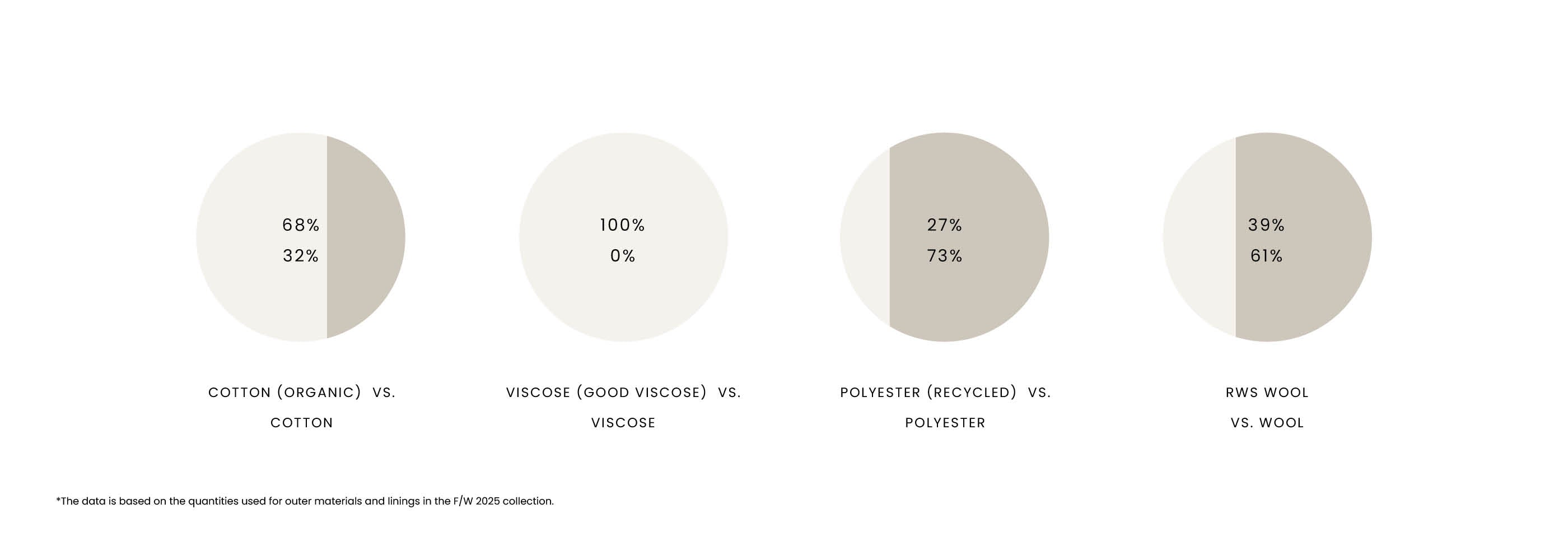

LOWER-IMPACT VS. CONVENTIONAL MATERIALS

PARTNERS & PRODUCTION

STRENGTHENING REGIONAL PRODUCTION PATHWAYS

For our Fall/Winter 2025 collection, production was largely centred in Europe, with 76% of all garments manufactured within European partner facilities (F/W 2024: 67%). This reflects our focus on regional supply chains that offer shorter transport routes, greater transparency, and closer collaboration.

While seasonal category mixes naturally influence country distribution, F/W 2025 shows a more balanced spread across our partner network. Romania and North Macedonia increased their contribution this season, while China continued to support specialised product categories where technical expertise is key. These shifts are part of a dynamic sourcing landscape and reflect the requirements of this specific collection.

Earlier production stages follow a similar pattern: just over 60% of weaving and dyeing took place in Europe, particularly in Italy, Portugal, Lithuania, Turkey, Bulgaria, Czech Republic, and Spain. China remained an important partner for articles requiring a high amount of specialized hand finishing, accounting for 29% of weaving and 28% of dyeing.

Across all partnerships, we prioritise transparency and high product quality. While the sourcing landscape continues to evolve, F/W 2025 demonstrates the value of a strong regional foundation combined with the expertise of carefully selected global partners.

*Please note that each season's data is shaped by the category mix, specific designs, and the expertise of the respective suppliers.

WHERE WERE THE FABRICS PRODUCED?

Country of Weaving

Country of Dyeing

Where was our collection produced?

STRENGTHENING OUR FOUNDATION AND JOINING FORCES FOR LONG-TERM GROWTH

Fall 2025 marked an important moment for IVY OAK, as we established a new company structure in partnership with DK Company. This step connects our brand to one of Europe’s leading fashion groups, allowing both sides to benefit from shared knowledge, complementary strengths, and a long-term perspective on quality and craftsmanship.

For IVY OAK, this partnership means access to broader expertise across sourcing, materials, and environmental initiatives, supported by DK Company’s dedicated ESG structures and specialist teams. At the same time, we contribute our design-led approach and experience in long-lasting product development within a group that emphasises durability and long-term value creation.

Together, this allows us to deepen how we work with materials, strengthen IVY OAK’s operational foundation, and continue evolving our environmental and social ambitions in a meaningful, steady way.

GIVING DESIGN SAMPLES A SECOND LIFE

Reducing waste is an important part of our approach to circularity. As part of this effort, design samples that cannot be sold are repurposed rather than discarded. We regularly donate these items to local partners and social organisations in Berlin.

Our most recent donation went to Caritas Frauenhaus (Caritas Women’s Shelter), supporting women in need while extending the useful life of these items.

STRENGTHENING OUR FOUNDATION AND JOINING FORCES FOR LONG-TERM GROWTH

Fall 2025 marked an important moment for IVY OAK, as we established a new company structure in partnership with DK Company. This step connects our brand to one of Europe’s leading fashion groups, allowing both sides to benefit from shared knowledge, complementary strengths, and a long-term perspective on quality and craftsmanship.

For IVY OAK, this partnership means access to broader expertise across sourcing, materials, and environmental initiatives, supported by DK Company’s dedicated ESG structures and specialist teams. At the same time, we contribute our design-led approach and experience in long-lasting product development within a group that emphasises durability and long-term value creation.

Together, this allows us to deepen how we work with materials, strengthen IVY OAK’s operational foundation, and continue evolving our environmental and social ambitions in a meaningful, steady way.

GIVING DESIGN SAMPLES A SECOND LIFE

Reducing waste is an important part of our approach to circularity. As part of this effort, design samples that cannot be sold are repurposed rather than discarded. We regularly donate these items to local partners and social organisations in Berlin.

Our most recent donation went to Caritas Frauenhaus (Caritas Women’s Shelter), supporting women in need while extending the useful life of these items.

FOOTPRINT

LOWERING EMISSIONS ACROSS OUR DAILY OPERATIONS

We are committed to continuously lowering the CO₂ emissions generated through our daily operations – from shipping and returns to our online shop to business travel. While some emissions remain unavoidable today, we focus on reducing them wherever possible and compensating the rest through certified climate projects.

In the first half of 2025, our activities resulted in 20.87 tons of CO₂ emissions, with the majority coming from shipments, followed by website operations and videoconferencing, and essential business travel. This is 2 times the average per capita CO₂ emissions in Germany (10.3 tons)* and reflects a clear downward trend over time: from 52 t in 2024 H1 to 22.97 t in 2024 H2, and now 20.87 t in 2025 H1.

To compensate for the remaining emissions, we once again partnered with Klima-Kollekte, supporting Gold Standard-certified climate projects such as the Bagepalli Biogas Program in India. These projects replace traditional cooking fuels with biogas systems, improving health conditions, supporting sustainable farming practices, and helping women gain more time for education and personal development.

*Source: German Environment Agency, 2025